Plasma etching is a cornerstone technology in modern semiconductor research and fabrication. As device dimensions continue to shrink into the micro- and nanometer size, plasma-based dry etching processes have become indispensable for achieving the precision, structural properties, and material selectivity required in advanced microelectronics, nanotechnology, and optoelectronics. Choosing the appropriate plasma etching technique depends on factors such as feature size, aspect ratio, material system, surface quality requirements, and throughput. This article provides a technical overview of the most important plasma etching techniques – Reactive Ion Etching (RIE), Inductively Coupled Plasma Reactive Ion Etching (ICP RIE), Deep Reactive Ion Etching (DRIE), and Atomic Layer Etching (ALE) – highlighting their advantages, applications, and relevance in semiconductor research and fabrication.

Understanding Plasma Etching and How it Works

Fundamentally, plasma etching is a dry etching process in which a low-pressure plasma is used to remove material from a substrate surface. The plasma contains a mixture of ions, radicals, electrons, and neutral species generated from reactive gases such as fluorine- or chlorine-based chemistries. Material removal occurs through a combination of physical sputtering and chemical reactions at the surface.

Compared to wet chemical etching, plasma etching offers superior pattern fidelity, compatibility with photoresist or hard masks, and the ability to etch complex multilayer stacks with nanometer-scale control. By carefully controlling plasma parameters such as pressure, RF power, gas composition, substrate bias and plasma-immersion, engineers can tailor etch rate, anisotropy, selectivity, and surface damage. These advantages have made plasma etching essential for advanced semiconductor devices, MEMS, photonic structures, and emerging quantum and nanoelectronics applications.

Which is the Best Plasma Etching Technique?

To answer this question, it is necessary to first examine the respective strengths, limitations, and areas of application for each process. By examining key process characteristics such as etch rate, anisotropy, selectivity, surface quality, and scalability, it is possible to decide on the most appropriate plasma etching method for specific materials, device architectures, and fabrication requirements.

Comparing Reactive Ion Etching (RIE) and Inductively Coupled Plasma (ICP) -RIE

How Does Reactive Ion Etching Work?

Reactive Ion Etching is one of the most widely used plasma etching techniques in microfabrication. In RIE systems, a parallel-plate reactor configuration is typically employed, where RF power is applied to generate a plasma and bias the substrate. The applied bias accelerates ions toward the wafer surface, providing directional (anisotropic) etching through combined chemical and physical interactions.

Why Choose RIE?

RIE offers a good balance between chemical selectivity and physical directionality. It enables anisotropic profiles essential for defining fine features while maintaining relatively simple hardware and process control. RIE systems are cost-effective, versatile, and well-suited for research laboratories and small-scale production environments, although etch rates and plasma densities are limited compared to high-density plasma systems.

RIE is commonly used in semiconductor research and microelectronics. Typical applications include patterning of silicon, silicon dioxide, silicon nitride, III–V semiconductors, and metal layers. In optoelectronics, RIE is frequently applied to fabricate waveguides, gratings, and photonic crystal structures where moderate aspect ratios and precise lateral dimensions are required.

Despite its versatility, Reactive Ion Etching has several inherent limitations. Plasma density in conventional RIE systems is relatively low, which restricts achievable etch rates and makes the technique less suitable for deep or high-aspect-ratio structures. Because ion energy and plasma density are coupled, increasing directionality often leads to higher ion bombardment energies, which can cause substrate damage, mask erosion, and reduced selectivity.

RIE also exhibits limited process windows for advanced nanoscale pattern transfer, particularly when etching dense or heterogeneous material stacks. Micro loading effects and non-uniformity across larger wafers can become significant, especially in research tools without advanced plasma uniformity control. As a result, RIE is increasingly supplemented or replaced by high-density plasma techniques for advanced device fabrication.

ICP-RIE, which is used in many SENTECH plasma processing systems, is an advanced form of RIE that decouples plasma density from ion energy. In an ICP-RIE-based system, such as the SENTECH SI 500 system, an inductively coupled RF source generates a high-density plasma, while a separate RF bias controls the ion energy at the substrate.

What are the Advantages of ICP-RIE?

The key advantage of ICP-RIE is its high plasma density, which enables significantly higher etch rates and improved process control compared to conventional RIE. A high degree of independent control of ion flux and ion energy allows for excellent anisotropy, high selectivity, and reduced substrate damage. This makes ICP-RIE particularly suitable for nanoscale pattern transfer and sensitive materials. ICP-RIE is widely used in advanced semiconductor fabrication, nanotechnology research, and compound semiconductor processing. It is a preferred technique for etching high-aspect-ratio nanostructures, photonic devices, GaN- and SiC-based power electronics, and optoelectronic components such as LEDs and laser diodes. Research institutes rely on ICP-RIE for its flexibility and reproducibility. While ICP-RIE offers superior performance compared to conventional RIE, it introduces additional system complexity and cost. The wide parameter space of ICP-RIE requires expert process development to fully exploit its advantages, which can increase development time in research environments.

What are the Key Features and Applications of DRIE and Cryogenic Etching?

When to use Deep Reactive Ion Etching (DRIE)?

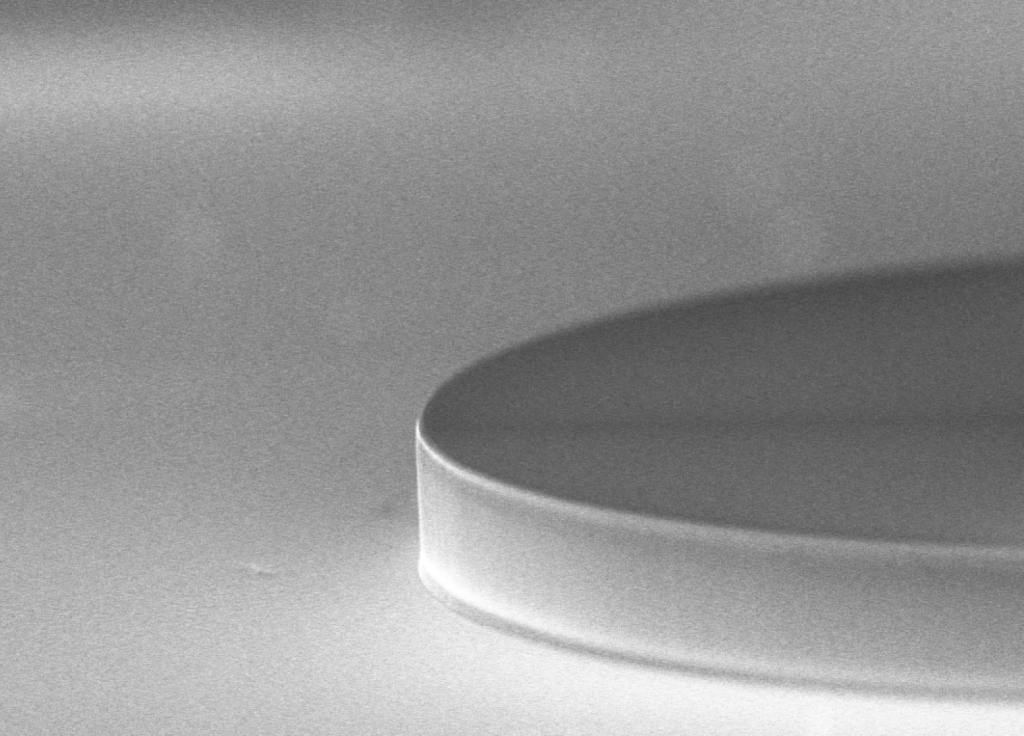

Deep Reactive Ion Etching (DRIE) is a specialised plasma etching technique designed to create extremely high-aspect-ratio structures, particularly in silicon. DRIE is most commonly implemented using the Bosch process, which alternates between etching and passivation steps to achieve near-vertical sidewalls.

DRIE enables etch depths of hundreds of micrometres with high aspect ratios, while maintaining excellent vertical sidewall integrity. This capability is unmatched by other etching techniques and is critical for three-dimensional microfabrication. DRIE also offers good uniformity across the wafer and compatibility with standard lithographic masks.

DRIE is essential in MEMS fabrication, where deep trenches, cavities, and through-silicon vias (TSVs) are required. Applications span inertial sensors, pressure sensors, microfluidic devices, and RF MEMS. In optoelectronics and micro-optics, DRIE is used to fabricate deep silicon structures for optical alignment, packaging, and photonic integration. The technique is widely adopted in both research and industrial manufacturing.

The primary limitation of DRIE, particularly Bosch-process DRIE, is firstly that it can only be used to etch silicon and secondly, sidewall roughness caused by the cyclic etch-passivation sequence, resulting in characteristic scalloping. While often acceptable for MEMS applications, this roughness can be detrimental in photonic or optical devices where scattering losses are critical. DRIE processes also suffer from aspect-ratio-dependent etching (ARDE), micro loading, and pattern-density effects, which can lead to non-uniform etch depths across the wafer. Mask selectivity, although generally good, becomes a limiting factor for extremely deep etches, often necessitating thick photoresist or hard masks.

Continuous DRIE processes have been developed for various other materials such as SiC, compound semiconductors, quartz and technical glass, and many more. They share the exploitation of high plasma density combined with high ion acceleration by bias to drive structures deep into bulk material.

What is the Benefit of Cryogenic Plasma Etching compared to DRIE?

Cryogenic plasma etching of silicon is a specialised etching technique that enables highly anisotropic profiles with exceptionally smooth sidewalls by operating the substrate at cryogenic temperatures, typically between −80 °C and −140 °C. The low process temperature leads to a chemical self-passivation on the sidewall by a SiOxFy layer, which is volatile at room temperature, and to a substrate free of polymer residuals. Originally developed as an alternative to the Bosch DRIE process, cryogenic etching achieves anisotropy through temperature-controlled surface chemistry rather than etch–passivation cycles. New types of cryogenic processing of materials other than silicon are under investigation.

How Does Cryogenic Plasma Etching Work?

In cryogenic etching, silicon is typically etched using an SF₆/O₂ plasma while the wafer is cooled to cryogenic temperatures using liquid nitrogen (LN2). Under these conditions, oxygen-assisted reactions lead to the formation of a thin SiOxFy passivation layer on the sidewalls, which suppresses lateral etching. At the same time, ion bombardment at the trench bottom continuously removes this layer, allowing vertical material removal to proceed. The balance between ion energy, oxygen concentration, and substrate temperature determines the degree of anisotropy and etch rate.

Unlike the Bosch process, cryogenic etching operates in a continuous mode and does not rely on polymer-based passivation, resulting in smooth sidewalls and the absence of scalloping artefacts associated with cyclic DRIE processes.

The primary advantage of cryogenic plasma etching is its ability to produce vertical silicon structures with very low sidewall roughness, which is difficult to achieve using conventional DRIE. High aspect ratios can be obtained, particularly for narrow structures, while maintaining excellent dimensional fidelity. These characteristics make cryogenic etching especially attractive for applications where surface quality is critical.

However, cryogenic etching requires precise control of wafer temperature and thermal uniformity, typically achieved through helium backside cooling and specialised chuck designs. The cryogenic DRIE process can be more sensitive to pattern-density and wafer-loading effects than Bosch DRIE. In addition, mask selectivity is often lower due to the continuous etching mechanism, which can limit the achievable etch depth when using photoresist masks. Combined with the reduced mechanical stability and adhesion of photoresists at cryogenic temperatures, this frequently necessitates the use of hard masks (e.g., SiO₂ or Si₃N₄) for deep or high-aspect-ratio etches.

Cryogenic plasma etching alongside DRIE is used in MEMS, as well as in silicon photonics and micro-optical device fabrication, where smooth sidewalls and precise feature definition are essential. Typical applications include silicon waveguides, photonic crystal structures, high-Q optical resonators, and microfluidic channels. The technique has gained renewed interest for advanced photonic and quantum devices, where sidewall roughness and surface damage can significantly impact device performance.

What is Atomic Layer Etching (ALE)?

Compared to other techniques, atomic layer etching (ALE) represents the next evolution of plasma etching precision and control, enabling material removal with atomic-scale precision. ALE is based on self-limiting, time- or chemistry-limited surface reactions that precisely remove material, namely one atomic layer at a time, through sequential, cyclic processing steps.

The primary advantage of ALE is unparalleled control over etch depth, uniformity, and damage reduction. Because material removal is limited per step, ALE minimises variability and enables angstrom-level precision. This is critical for advanced nodes in semiconductor technology, where even slight deviations can impact device performance.

When is ALE the right choice?

ALE is particularly suited for leading-edge semiconductor research, including logic and memory devices at the nanometer scale. It is also gaining importance in quantum devices, advanced optoelectronics, and heterogeneous integration, where ultra-thin layers and interfaces must be precisely engineered. ALE is primarily used in R&D environments and early-stage industrial adoption for next-generation technologies. Other fields of application, such as nano-/micro-optics and photonics, explore ALE for the benefit of its smoothening effect.

Although Atomic Layer Etching offers unmatched precision, its primary limitation is throughput. Because material removal occurs one atomic layer per cycle, ALE is inherently slower than continuous plasma etching techniques.

Plasma Etching Tools from SENTECH

How Do SENTECH Plasma Etching Systems Support Advanced Research and Manufacturing?

SENTECH offers a comprehensive portfolio of plasma etching tools tailored to the needs of semiconductor research, micro- and nanofabrication, and optoelectronics. SENTECH systems are designed with flexibility, precision, and reliability in mind, enabling users to perform RIE, ICP-RIE, DRIE, and ALE processes within a single platform or a modular cluster configuration.

SENTECH plasma etching tools provide precise control over key process parameters such as plasma density, ion energy, gas flow, and temperature, capabilities that align with the fundamental plasma processing requirements described in the literature. This level of control is essential for reproducible nanoscale fabrication and advanced materials research. Modular system architectures allow customisation for specific applications, from compound semiconductors and photonic devices to MEMS and emerging quantum technologies.

With a strong focus on research and small to mid-scale production environments, SENTECH supports process development from early experimentation to scalable fabrication. SENTECH plasma etching solutions are widely used in universities, research institutes, and industrial production worldwide, helping to advance innovation in microelectronics, nanotechnology, and optoelectronics, bridging the gap from lab to fab.

SENTECH has on-site plasma and metrology application labs where our team of experts can support you with process optimisation for your applications. All you need to do is contact our team to discuss sending us your samples.

Conclusion

Plasma etching remains a fundamental technology for modern semiconductor fabrication, enabling precise pattern transfer across a wide range of materials and dimensions. From the versatility of RIE and the high performance of ICP-RIE, to the extreme aspect ratios achieved with DRIE and the atomic-scale precision of ALE, each technique plays a vital role in today’s research and industrial landscapes. With advanced plasma etching tools from SENTECH, researchers and engineers are equipped to meet the challenges of next-generation semiconductor, nanotechnology, and optoelectronic devices.